Headline for Post forming laminates here!

Let your imagination loose on your laminates. Allow us to customize your world with our collection of laminates with digital impressions. Or design your own laminate and share it with us - it can be an image or any other design. We will help you convert your imagination into reality on our laminates..

VIOFLEX Post Forming Laminate range has been exclusively designed for usage on vertical and horizontal interior surfaces where the laminate is required to roll in a simple radius over the edges of a substrate. With added flexibility, malleability and excellent thermoforming properties for forward and reverse bending applications, VIOFLEX Post Forming Laminate enhances the decorative property of the edges of any regular laminate since it gives no seams around corners and a smooth, evenly laminated surface.

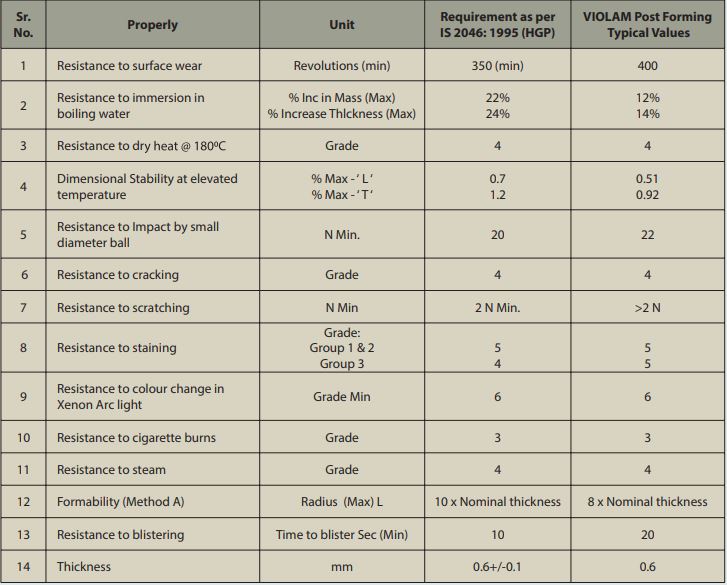

VIOFLEX Post Forming Laminates are fully cured Post Forming laminates that are manufactured using a controlled reaction process. In this process, the resin is allowed to cure fully but the reaction is controlled in such a way that even extra heating will not have an effect on its post forming properties. As these laminates are fully cured, they inherit and exhibit exactly the same properties as general purpose laminates

- Shutters

- Countertops

- Furniture tops

- Executive tables

- Modular office systems

- Computer workstations

- Kitchen cabinet doors & shutters

- Shelving systems

- Shelving systems

SAWING : To avoid chipping, it is important that the saw blade teeth cut into the decorative face.

CIRCULAR SAWING : To avoid vibration that causes chipping, make sure to provide support to the material near the point of blade contact.

ROUTING : Electric or air powered carbide tip routers could be used for routing. Recommended router speed is 16000 to 22000 rpm. For special edge trimming very high speed routers should be used to achieve smooth-edge chip-free work.

EDGE FINISHING : Belt sanders may be used to flush the self-edge before the laminate top is applied.

ADHESIVES : Special Post Forming Adhesive is recommended.

PROTECTIVE FILM : The protective film should be removed as soon as the application is complete. Else exposure to strong lights may cause a pale residue and make it difficult to remove the protective film.